Techno Flex Cables An Instrumentation Cables is planned with numerous conveyors which are utilized to send low-energy electric signs. The three primary targets of an instrumentation link are to quantify, direct and to control the electrical framework and its different assistant cycles. These Instrumental Cables convey low-energy flags that empower coordinating or following of high-stakes electronic circuit-subordinate capacities. Because of this, Instrumentation Cables assume a very essential part in handling and assembling tasks, for example, designing businesses and power dispersion plants.

These cables are accessible according to their development for example Development: Cores/Pairs/Triads/Quads. These Core/Pair/Triad/Quad are gathered in concentric or unit Formation with reasonable Lay Length. We, at Techno flex cables guarantee cautious and intensive endeavors in supporting principles and stringently implemented process control during improvement and assembling.

For more information you can contact our experts through our mobile number to assist in giving you more detailed information to meet your requirements. We Techno flex cable are acclaimed to be the best in the field and give our competitors a tough fight with regards to our quality and rates! Time and again we have proved that we are better than the best !

Techno flex cable is one of the best Instrumentation Cable manufacturer, Instrumentation Cable exporter, Instrumentation Cable supplier in Mumbai, India. We serve in all over countries. If you want this product then please quote here !

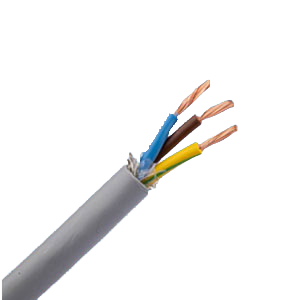

CONDUCTOR :

Annealed bare/ uniform coated with Tinned/Silver Platted, High Conductivity, and Electrolytic Grade Solid/Stranded/Flexible Conductor.

INSULATION :

Conductor are insulated with General Purpose PE / HR / FRLS / LSZH / PVC Compound / or any other dielectric material as per customers specification.

COLOUR OF DIELECTRIC :

Cores are identified with different type of color scheme as per requirement as below:-

- As per IS:1554[Pt-I]:88, 694:90.

- As Per IEC, ITD or number Printing.

- As Per Customers Scheme.

PAIR/TRIAD/QUAD :

Two/Three/Four cores are uniformly twisted together to form a Pair/Triad/Quad with maximum lay length 80 mm/as per requirement of customer. The lay shall be so chosen as to minimize cross talk in the cable.

INDIVIDUAL SHIELDING :

If required, Individual Shielding may be of Poly Aluminum [Thin Layer of Aluminum Foil bonded to Polyester Film] Tape with Annealed Tinned Copper Drain Wire. It prevents the shorting of adjacent shield and minimizes the cross talk and ground loops. A Tinned Copper drain Wire is installed to provide continuous contact with the shield and allow to connection to ground. Tinning the drain wire reduces galvanic corrosion between drain and shield.

LAYING OF PAIRS/TRIAD/QUAD :

Pair/Triad/Quad are laid up with suitable lay. The outer most layers are right hand lay and successive layers are laid up with opposite lay. Then, a Polyster Tape is provided to bind up laid up Pair/Triad/Quad.

OVERALL SHIELDING :

If required, Overall Shielding may be of Annealed Tinned Copper Braiding / Poly Aluminum [Thin Layer of Aluminum Foil bonded to Polyester Film] Tape with Annealed Tinned Copper Drain Wire. Braiding ATC Shield has high tensile Strength and provides better coverage in flexing application. They are easier to terminate. This provides effective shielding; cross talk and noise are kept to an absolute minimum.

INNER SHEATH :

The laid up pair/triad/quad after shielding are provided with an inner sheath, which may be either Extruded Inner Sheath or wrap with PVC Tape.

ARMOURING :

It is applied over inner Sheath. It may consist of galvanized Round Steel wires or galvanized Flat Steel Strips.

OUTER SHEATH :

It is applied over Armouring in case of Armoured Cable or over Inner Sheath in case of Unarmoured Cable. The Color of Sheath is Black or Grey. The Sheath material may be General Purpose/HR / FRLS / LSZH PVC Compound as per requirement of specification.

TYPICAL APPLICATION :

For Connection of Instruments, Process Control Systems, Computers, Data Transmission etc.